Purchase maize flour milling machine at factory direct price

The maize milling machine is designed for the efficient and fast processing of maize into maize flour. It produces flour with a dense texture, enhances gluten strength, and improves the flexibility of the flour. Perfect for both personal use and profitable business ventures, the maize flour milling machine offers high-quality results.

KMEC Maize Flour Milling Machine for Sales

KEMC is a leading manufacturer of grain processing equipment, offering a complete range of services including engineering design, research and development, manufacturing, sales, and installation. We specialize in providing both primary and advanced grain processing machinery for maize, wheat, cassava, beans, chili, and other grains. Our maize flour milling equipment is ideal for both small-scale flour milling businesses and large commercial maize flour processing plants.

If you're looking to buy a maize milling machine, we are your BEST choice. We offer a wide range of types and models to meet every specific need. Additionally, we provide the most competitive prices in the international market while ensuring high-quality machines and optimal production efficiency. Among our maize processing equipment, the small-scale maize flour milling machine is the most popular, as it allows customers to easily start their own small-scale maize flour milling business. If you're interested, please contact us for the latest price list and machine specifications!

1~30TPD Small Maize Milling Machine

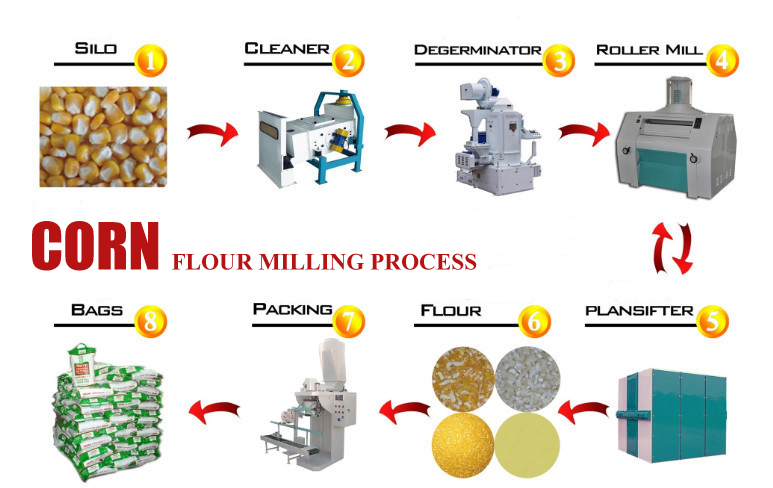

The maize flour milling process of small scale maize processing plant is divided into two parts: raw material cleaning and flour milling.

Maize Cleaning Process

The cleaning process involves one sieving, one brushing, and one destoning. Maize from the silo is lifted to the cleaning sieve and destoner by a bucket elevator. The impurities are removed based on their size, with larger and smaller impurities separated during the sieving process. After sieving, the material is sent to the destoner to remove stones. The cleaning sieve also has a suction dust removal fan, which helps remove small stones that the destoner couldn't eliminate, as well as the smallest impurities. Next, the raw materials pass through a wheat brushing machine to remove surface impurities like ash and mud, and further impurities are sieved out.

Maize Flour Milling Process

If peeling is required, two maize peeling machines are used to remove the husk and germ. After peeling, the maize goes through a crusher for preliminary crushing. The crushed materials are then ground by two flour mills and sieved to achieve the desired fineness of the maize flour. The maize flour that meets the standard is directly packed, while any flour that doesn't meet the quality standard is sent for further milling and sieving to reach the required fineness. Any final flour that still doesn't meet the standard is packaged as raw material for animal feed.

NF-90 Mini Maize Peeling Machine

Why is peeling necessary during the maize flour milling process? To produce high-quality maize products, the maize must undergo a peeling process. Peeling helps improve the quality of the final product by removing the husk and germ. Here are some of the key benefits of maize peeling:

- Improved Quality: Peeling removes unwanted parts like husk and germ, resulting in cleaner and more refined maize flour.

- Better Texture: The removal of the outer layers enhances the texture and consistency of the maize flour, making it more suitable for various applications.

- Increased Yield: Peeling reduces waste, ensuring more usable material is processed into high-quality flour.

- Enhanced Taste and Appearance: The removal of impurities leads to better-tasting and visually appealing maize products.

By using the NF-90 Mini Maize Peeling Machine, you can ensure a more efficient and effective peeling process, contributing to the overall quality of your maize flour production.

The Importance of Maize Peeling in the Milling Process

Maize peeling plays a crucial role in improving the efficiency and quality of maize flour production. Here are the key benefits of maize peeling:

- Enhanced Milling Efficiency: Peeling improves the degerming process, allowing maize milling machines to operate more efficiently and produce better-quality flour.

- Improved Product Quality: Maize husks are prone to contamination by pollutants. Removing the husk through peeling ensures a cleaner, safer final product.

- Better Taste and Texture: Peeling enhances the taste and texture of maize flour, making it more suitable for food production.

- Essential for High-Quality Production: Using maize processing machinery for peeling is essential in maize flour mills, as it significantly improves the overall quality of processed maize products.

To further enhance efficiency and productivity, maize shellers are also widely used in the maize processing industry.

Factors Determining Maize Flour Milling Machine Prices

Several factors influence the price of maize flour milling machines, including the place of production, energy efficiency, capacity, and quality.

- Place of Origin

The price of maize flour milling machines varies based on where they are manufactured. Factors such as local government policies, market demand, and consumer expectations impact the pricing. For example, a fully automatic maize flour milling machine costs around $8,000–$10,000 in China, whereas a similar machine in the United States is priced at $9,000–$11,000.

- Energy Efficiency

High-energy efficiency machines generally have a higher initial cost but offer long-term savings. A high-energy efficient maize flour milling machine with high output costs around $2,000–$3,000, while a lower-efficiency model is priced at $1,000–$1,850. Investing in an energy-efficient machine can help reduce fuel and electricity consumption over time.

- Capacity

Maize flour milling machines are categorized based on their production capacity: small-scale, medium-scale, and large-scale. Small-scale machines typically process 10 TPD (tons per day), whereas large-scale machines can handle up to 200 TPD.

- Quality

The quality of the machine significantly impacts its price. Well-known brands offering high-quality maize flour milling equipment tend to be more expensive. For instance, a high-quality home flour milling machine from a top brand is priced at $6,500–$9,000, while machines from other brands range between $5,000–$7,000.

When purchasing a maize flour milling machine, it’s essential to consider these factors to find the best balance between cost, efficiency, and performance.

The market offers a wide range of maize flour milling machines from various brands and manufacturers, each with different prices. Before purchasing a maize milling machine, it is essential to review the manufacturer’s terms and conditions to ensure you are getting a high-quality product.

For the best results, consider buying from reputable manufacturers who also supply grinding rollers, rings, and other related equipment, as they typically offer superior quality milling machines. Investing in a reliable and durable maize flour milling machine will ensure long-term efficiency and performance.